In the cosmetics industry, plastic packaging materials, as the "outer layer" of products, are not only directly related to the beauty of the product, but also closely related to the safety and convenience of use of the product. Therefore, the selection of cosmetic plastic packaging materials by OEMs (original equipment manufacturers) must strictly control quality and function, ensuring that both are equally important to meet market demand and consumer expectations.

Quality is the primary consideration for OEM purchasing of plastic packaging materials for cosmetics. High quality plastic packaging materials should have good physical properties, such as impact resistance and impact resistance, to ensure that products are not easily damaged during transportation and storage. At the same time, the chemical stability of packaging materials is also crucial, ensuring that they do not contain harmful substances and do not react with cosmetic ingredients, thereby ensuring the safety and stability of the product. In addition, the environmental friendliness of packaging materials cannot be ignored. The use of biodegradable or recyclable materials is conducive to reducing environmental pollution and in line with the current trend of green development.

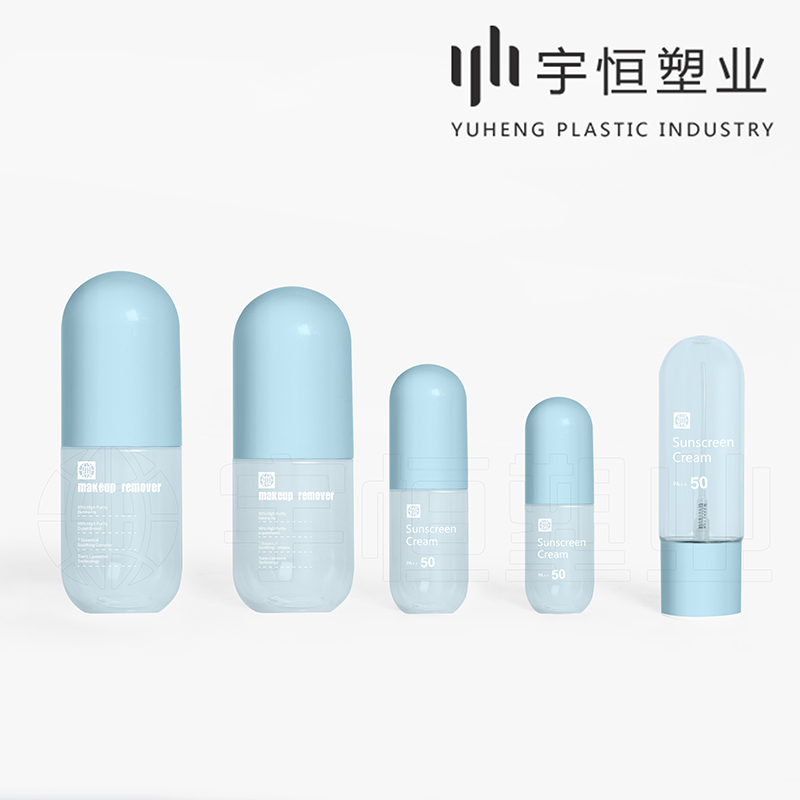

Function is another major focus for OEM purchasing of plastic packaging materials for cosmetics. The design of packaging materials should fully consider the usage habits and experiences of consumers, such as the bottle mouth design should be easy to pour and retrieve, and the bottle cap should be tight and easy to open. In addition, the sealing and anti leakage performance of packaging materials are also crucial to ensure that cosmetics do not leak or contaminate during storage and use. For some special types of cosmetics, such as sunscreen products, spray, etc., the packaging materials should also have special functions such as sunscreen, splash prevention, etc. to meet the specific needs of the product.

When choosing OEM plastic packaging materials for cosmetics, enterprises should also pay attention to the manufacturer's production capacity and service level. A strong OEM manufacturer typically possesses advanced production equipment and technology to ensure that the quality and performance of packaging materials meet industry standards. Meanwhile, a good level of service is also an important guarantee for cooperation, including timely technical support, flexible customization capabilities, and comprehensive after-sales service.

In summary, the OEM selection of plastic packaging materials for cosmetics must prioritize both quality and functionality. Enterprises should fully consider various factors such as the quality, function, and environmental friendliness of packaging materials in the selection process, and choose OEM manufacturers with strength and reputation for cooperation to ensure the quality and safety of products and enhance market competitiveness.