With the booming development of the cosmetics industry, plastic packaging bottles for cosmetics, as an important carrier of products, have received widespread attention from the industry in terms of material, technology, and market conditions. This article will delve into the material selection, production process, and market trends of plastic packaging bottles for cosmetics, providing valuable reference information for relevant enterprises and consumers.

1、 Material selection of plastic packaging bottles for cosmetics

There are various types of materials used in plastic packaging bottles for cosmetics, commonly including polyethylene (PE), polypropylene (PP), polyester (PET), etc. These materials have their own characteristics and meet the packaging needs of different cosmetics. For example, PE material has excellent flexibility and sealing properties, making it suitable for packaging liquid cosmetics; PP material has high heat and chemical resistance, making it suitable for cosmetics that require high-temperature disinfection or contain special ingredients; PET material is favored by the market for its high transparency, excellent impact resistance, and environmental performance.

2、 Production process of plastic packaging bottles for cosmetics

The production process of plastic packaging bottles for cosmetics includes various methods such as injection molding, blow molding, and extrusion. Injection molding technology is suitable for large-scale production, with high production efficiency and relatively low cost; The blow molding process can produce bottles with complex shapes and uniform wall thickness, suitable for packaging high-end cosmetics; The extrusion process can achieve continuous production and is suitable for the manufacturing of products such as films and pipes.

In the production process, manufacturers also need to pay attention to controlling key indicators such as precision, glossiness, and sealing of products to ensure that packaging bottles can meet the storage and use requirements of cosmetics. Meanwhile, with the increasing awareness of environmental protection, manufacturers also need to pay attention to the environmental friendliness of their production processes and reduce the discharge of waste and pollutants.

3、 Market trends of plastic packaging bottles for cosmetics

Currently, the plastic packaging bottle market for cosmetics is showing the following trends:

Green environmental protection has become mainstream. As consumers increasingly pay attention to environmental issues, cosmetics manufacturers and packaging bottle manufacturers are actively seeking environmentally friendly materials and production processes to reduce their impact on the environment. For example, measures such as using biodegradable materials and promoting recycling can reduce the generation of waste.

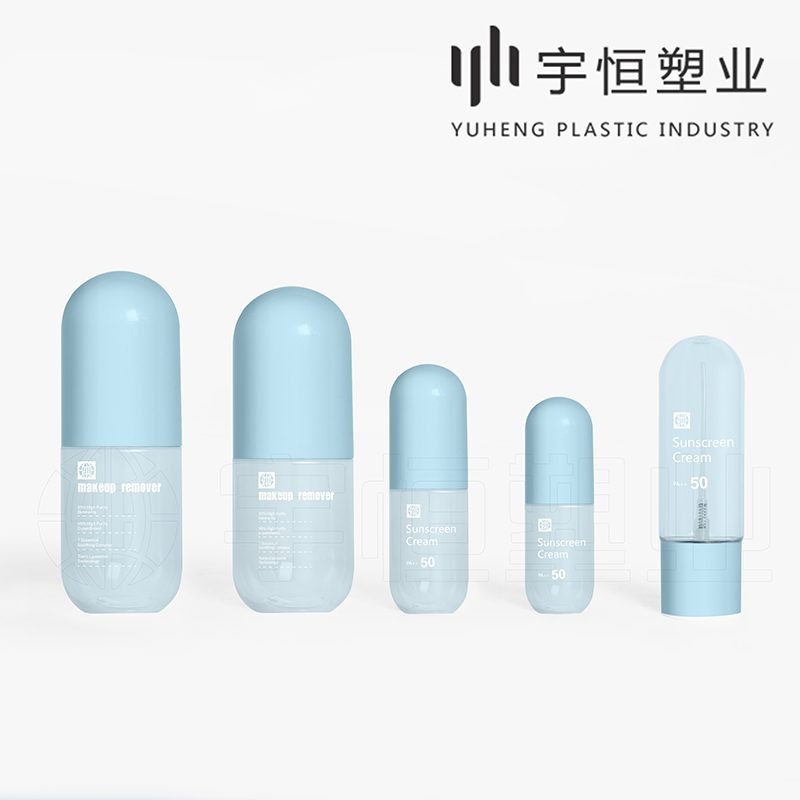

Personalized design is in high demand. In the fierce market competition, cosmetics brands have put in effort in packaging design to attract consumers' attention. Plastic packaging bottles have become an ideal choice for personalized design due to their strong plasticity and low cost advantages. Manufacturers can customize unique shapes, colors, and patterns based on brand positioning and consumer needs to enhance product added value and market competitiveness.

Intelligent packaging is emerging. With the development of technology, intelligent packaging has gradually become a new favorite in the cosmetics industry. By adding smart tags, QR codes, and other technological means on packaging bottles, product information traceability, anti-counterfeiting, interaction, and other functions can be achieved, enhancing consumer shopping experience and brand trust.

In summary, plastic packaging bottles for cosmetics are an important component of the cosmetics industry, and their materials, processes, and market trends are constantly evolving and changing. Manufacturers need to keep up with the pulse of the market, constantly innovate and improve to meet the needs of consumers and the development of the industry. At the same time, attention should also be paid to environmental protection and sustainable development issues, contributing to the healthy development of the industry.