In the cosmetics industry, plastic bottles serve as a vital packaging form, not only fulfilling the basic function of product protection but also acting as a crucial carrier of brand image and consumer experience. Therefore, selecting the right plastic bottle packaging material for cosmetics is paramount. Here are ten core rules for purchasing cosmetic plastic bottle packaging materials to help you make informed decisions amidst numerous options.

1. Clarify Product Positioning and Market Demand

The first task is to clearly define the product positioning and target consumer group, understanding market demand trends, including environmental requirements and consumer preferences, to select suitable plastic bottle types and design styles.

2. Evaluate Material Safety

Ensure the selected plastic materials comply with domestic and international safety standards, such as being BPA-free (Bisphenol A), meeting FDA (Food and Drug Administration, USA) and EU regulations, guaranteeing the safety of products for consumers.

3. Consider Material Stability and Compatibility

Choose materials that are compatible with the cosmetic contents (e.g., pH level, oil content), preventing product degradation or packaging deformation due to chemical reactions.

4. Focus on Environmental Protection and Sustainability

Prioritize recyclable, biodegradable, or made from recycled materials plastic bottles to align with eco-friendly trends and enhance brand image.

5. Assess Cost-Effectiveness

Comprehensively evaluate factors like material costs, production efficiency, mold expenses, and transportation costs to ensure cost optimization while maintaining quality.

6. Pay Attention to Design Aesthetics

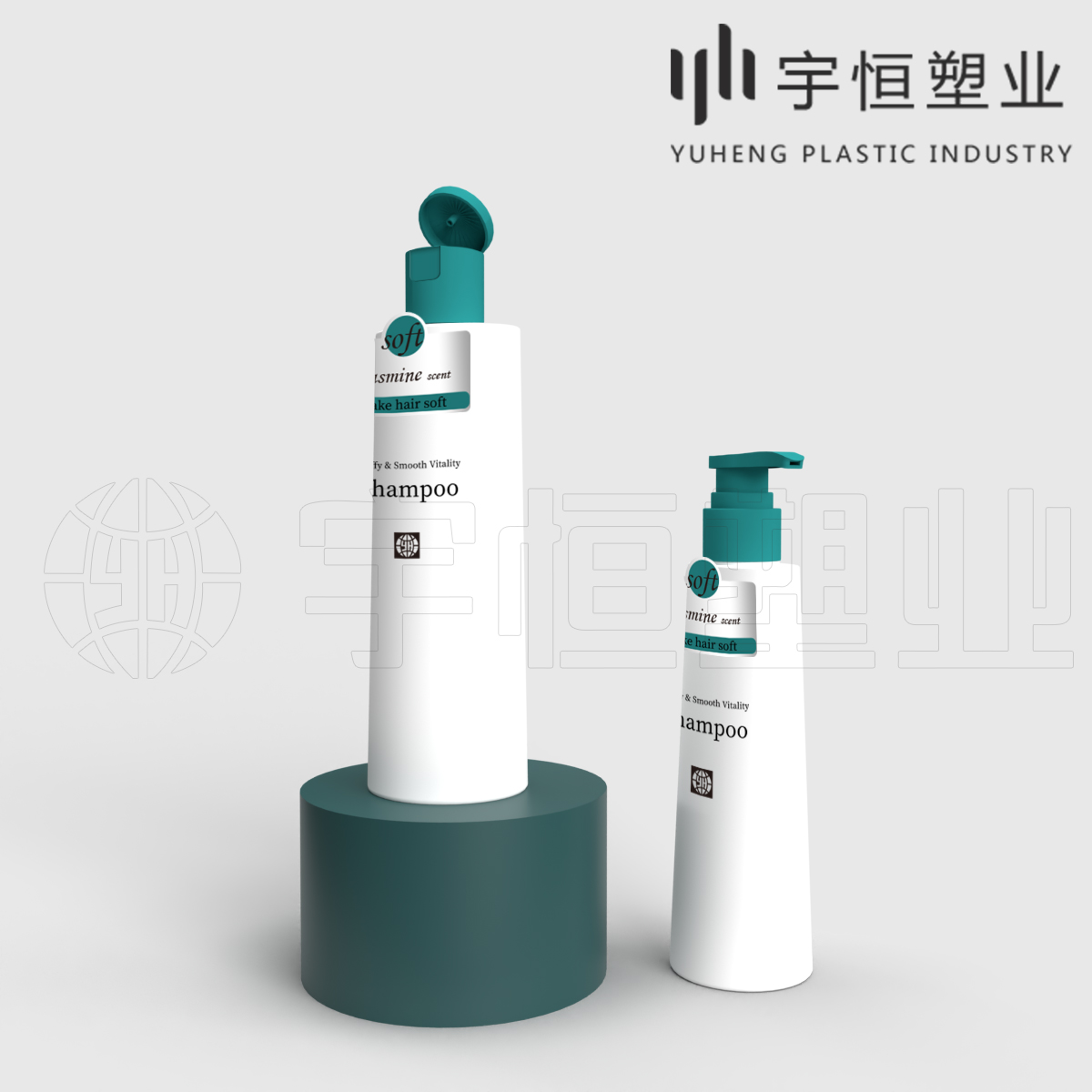

Plastic bottle designs should align with brand tonality, attracting target consumers. Consider factors like color, shape, and surface treatments (e.g., matte, pearlescent) to enhance product appeal.

7. Test Sealability and Durability

Ensure plastic bottles have excellent sealing performance to prevent content leakage or spoilage. Additionally, conduct drop and pressure tests to guarantee safety during transportation and use.

8. Review Supplier Qualifications

Select qualified and reputable suppliers, evaluating their production capacity, quality management systems, and after-sales service to ensure a stable and reliable supply chain.

9. Prototype Testing and Evaluation

Before mass production, conduct small-batch prototyping to assess the plastic bottles' actual performance, including appearance, feel, and functionality, making adjustments as necessary.

10. Continuous Monitoring and Feedback

Establish a quality control mechanism to conduct periodic spot checks on purchased plastic bottles, ensuring ongoing compliance with standards. Simultaneously, collect market feedback to continually optimize packaging solutions and enhance user experience.

By adhering to these ten rules, you can make more scientific and rational decisions during the procurement process of cosmetic plastic bottle packaging materials, enhancing your products while safeguarding the long-term development of your brand.