In today's fiercely competitive cosmetics market, product packaging serves not only as a physical barrier to protect the product from damage but also as a direct manifestation of brand image, playing a crucial role in attracting consumer attention and conveying brand value. Therefore, selecting a cosmetics plastic bottle packaging material OEM factory that aligns with your brand positioning is vital for enhancing product competitiveness and shaping brand image. Below are some key steps and considerations to guide you in making an informed decision.

Clarify Brand Positioning and Target Market

Firstly, clearly define your brand positioning, including the target consumer group, price range, product features, and market positioning (e.g., high-end, mid-range, or mass market). This will help you understand the desired texture, design style, and cost expectations of the packaging materials, laying a foundation for subsequent screening of OEM factories.

Research the OEM Factory's Professional Capabilities and Experience

Industry Experience: Check the OEM factory's years of experience in the cosmetics plastic bottle packaging field, whether they have served clients with similar brand positioning to yours, and the diversity of their successful cases.

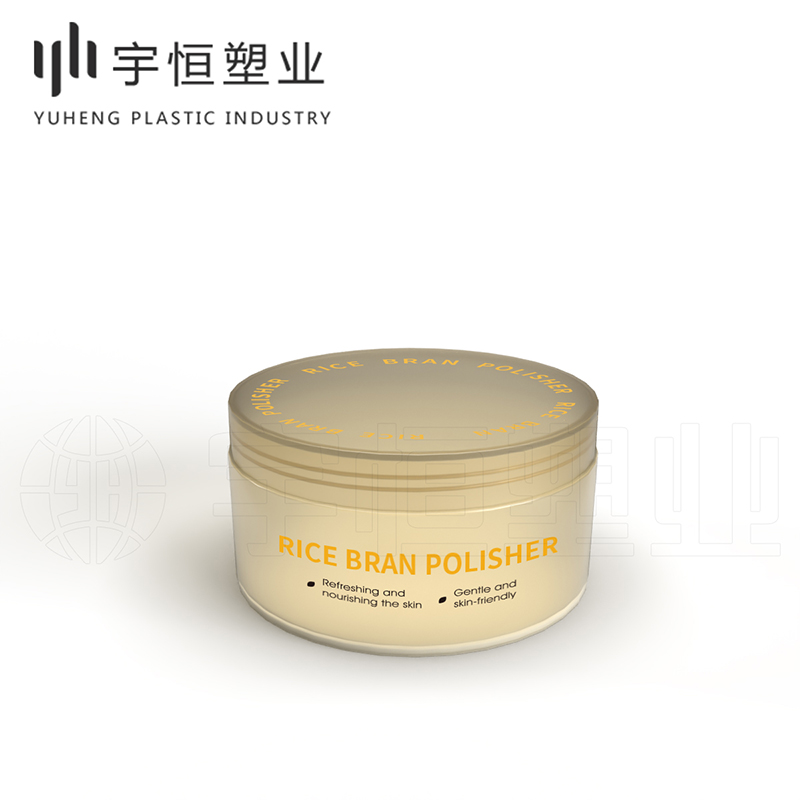

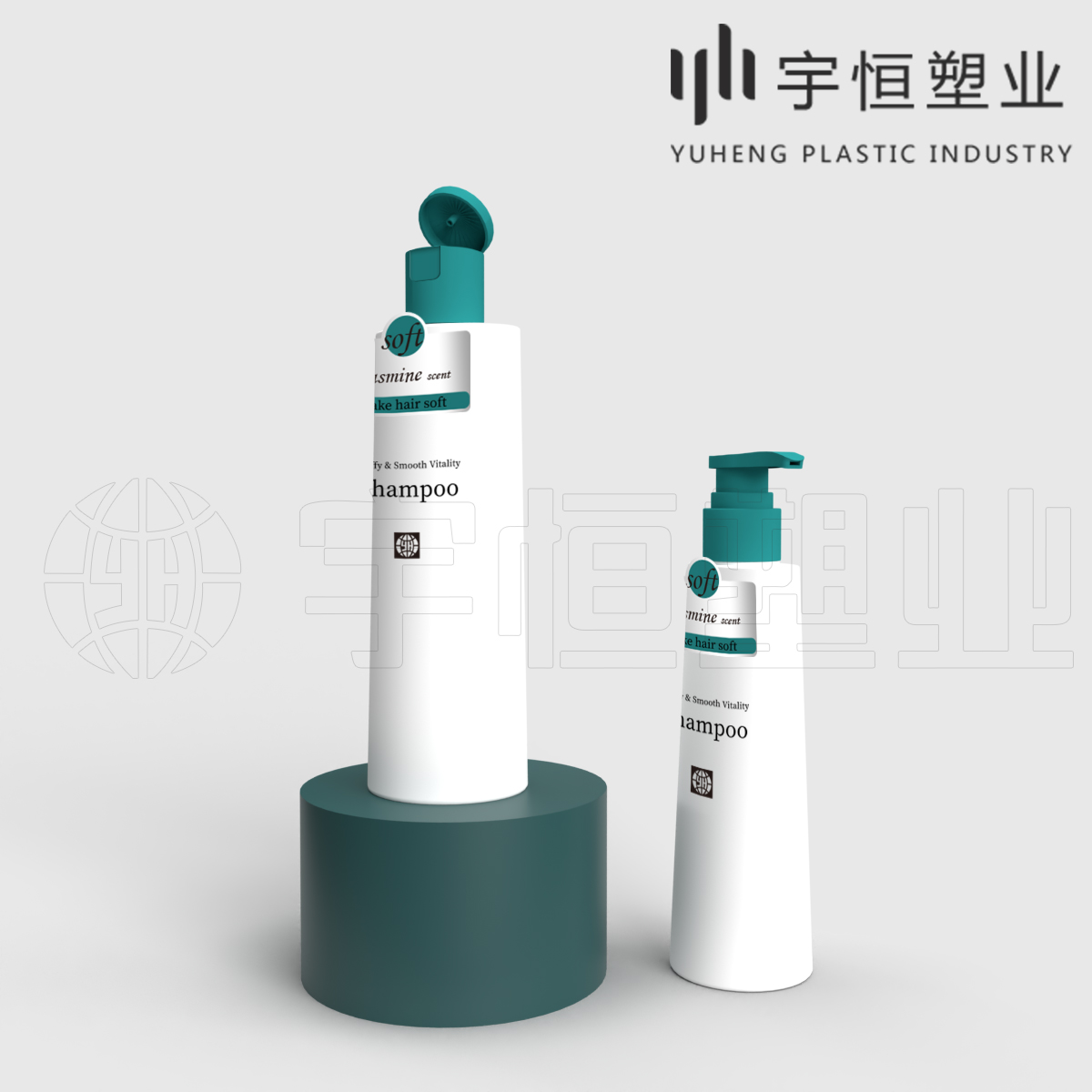

Technical Strength: Evaluate their design capabilities, mold development technology, injection molding processes, and the advancement of surface treatments (such as hot stamping, printing, UV coating, etc.) to ensure they can meet your demands for packaging uniqueness and high quality.

Production Capacity: Understand their production line scale, production flexibility, and delivery cycles to ensure they can respond quickly to fluctuations in market demand.

Inspect the Quality Control System

Quality Certifications: Verify if the OEM factory has passed international quality management system certifications such as ISO and GMP, which are crucial indicators of their quality management level.

Testing Methods: Ensure they possess comprehensive testing equipment and methodologies to guarantee that each batch of products meets the established quality standards.

Sample Evaluation: Request samples and conduct detailed evaluations, including appearance, dimensional accuracy, durability, and sealing performance, to judge their quality level based on actual experience.

Environmental Protection and Sustainability Considerations

With consumers becoming more environmentally conscious, choosing an OEM factory that uses eco-friendly materials is becoming a trend. Focus on whether the factory adopts recyclable, biodegradable, or low-impact plastic materials and whether they hold relevant environmental certifications or plans.

Communication and Collaboration Capabilities

Response Speed: Test the OEM factory's responsiveness to inquiries, sample requests, etc., to assess their service efficiency and attitude.

Customization Capabilities: Inquire about their support for personalized customization and their ability to provide innovative design suggestions based on your brand philosophy and market trends.

Communication and Collaboration: Establish a smooth communication mechanism to ensure close cooperation in design, production, logistics, and other aspects, minimizing misunderstandings and delays.

Cost-Benefit Analysis

Comprehensively consider the OEM factory's quotation, production efficiency, quality control, service level, and other factors to conduct a cost-benefit analysis. Avoid solely pursuing low prices at the risk of overlooking hidden costs in long-term cooperation.

Selecting a suitable cosmetics plastic bottle packaging material OEM factory that aligns with your brand positioning involves a holistic consideration of brand needs, market trends, technical capabilities, quality control, environmental philosophy, and cost-effectiveness. Through meticulous market research, rigorous screening criteria, and effective communication and collaboration, you will be able to find the partner that can propel your brand to new heights.